PP Packing Strap Making Machine

PP packing strap making machine which can produce one and two strap in one time,

the raw material can be 100% PP recycled granules, it is better if virgin materials, it will be better. This kind of strip is widely used in the packing of kinds of fields such as carton box, general merchandise, electrical equipment, medicine, etc.

Fill out my online form.

Related machine:

1. pet packing strap making machine

| Model | SJ-65 | SJ-75 | SJ-90 |

| Extruder | SJ-65/30 | SJ-75/33 | SJ-90/33 |

| Productivity | 60-100kg/h | 80-120kg/h | 120-150kg/h |

| Drive Motor | 22kw | 30kw | 55kw |

| Two-station Winder | 60-120m/min,adjustable | ||

| Strap Size | Width:5mm-20mm | Width:10mm-25mm | Width:20mm-35mm |

| Thickness:0.36mm-1.0mm | Thickness:0.5mm-1.3mm | Thickness:0.5mm-1.8mm | |

| Installed Capacity | about80kw | about 90kw | about110kw |

| Line Dimension | 30m×2m×2.2m (L×W×H) | 30m×3m×4.5m (L×W×H) | 30m×5m×6m (L×W×H) |

Main machine list:

Function :

Heat and melt the pp for pp strap molding

Heat and melt the pp for pp strap molding

Function:

Cool the straps to a particular shape for next step

Cool the straps to a particular shape for next step

Function:

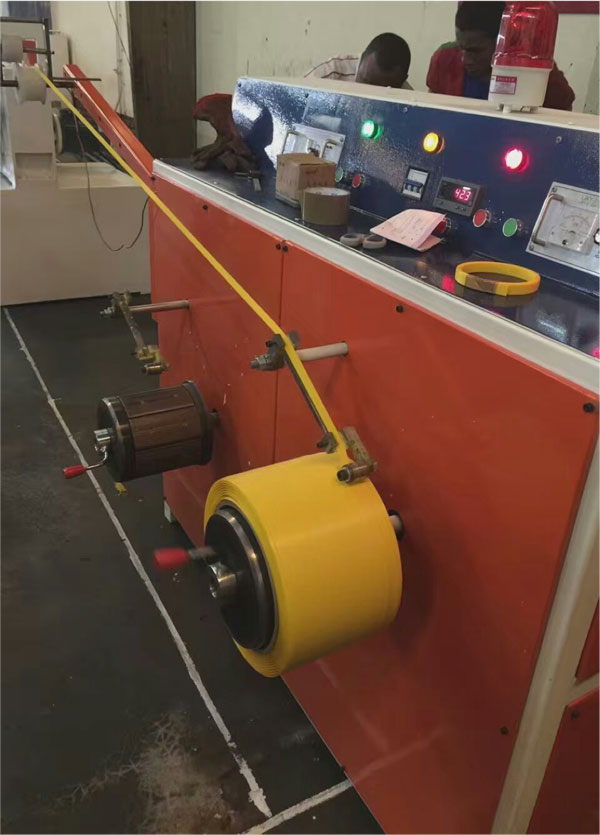

Tration,heat stretch, and emboss the belt strap.

Tration,heat stretch, and emboss the belt strap.

Function :

Remove the internal stress from the packing belt for getting good products.

Remove the internal stress from the packing belt for getting good products.

Function:

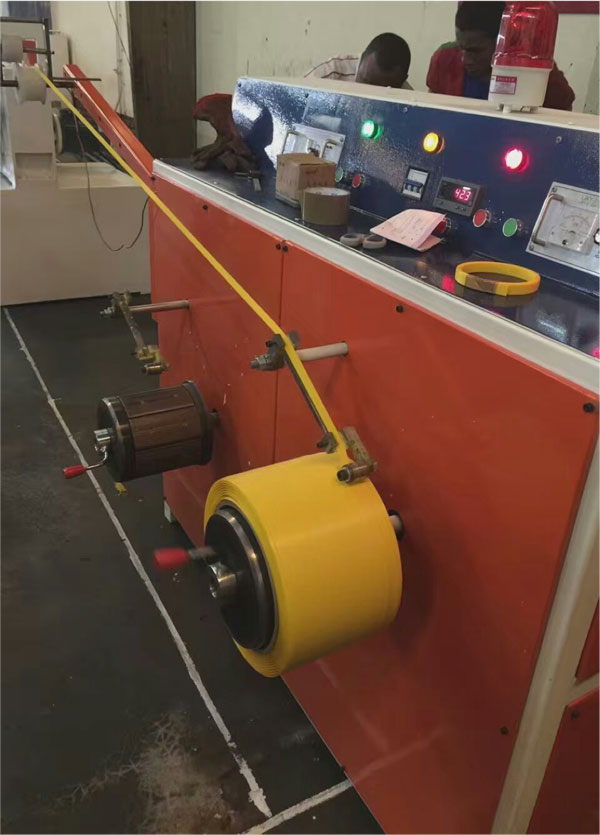

Wind the final products for easy stock

Wind the final products for easy stock