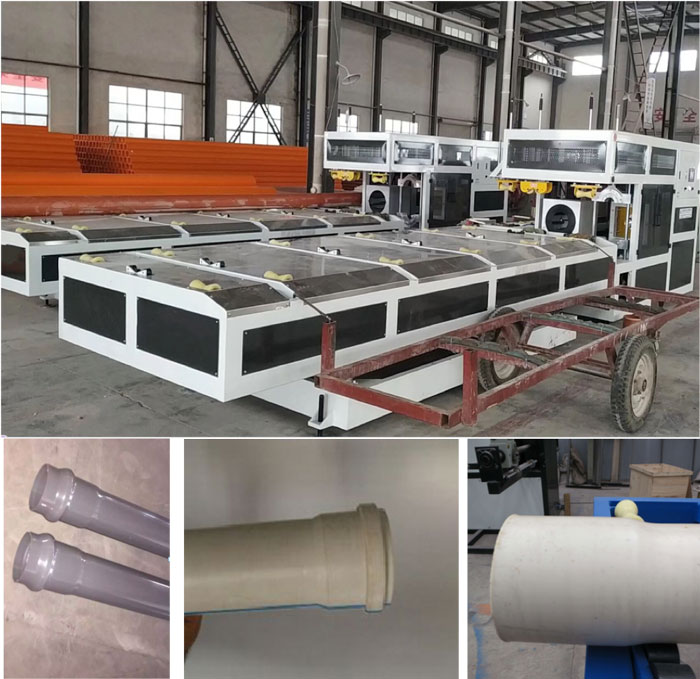

PVC Pipe Production Line

PVC pipe production line is mainly applied to produce agricultural water supply and drainage, building water supply and drainage, conduit of wire cables,the diameter and wall thickness of PVC pipes is customized.

The unit consists of conical twin-screw extruder, cavuum calibration and cooling tank, tractor, cutting machine and stacker, etc.

| Main extruer | SJZ65/132 | SJZ80/156 | SJZ92/188 | SJZ110/220 | |||||||||

| pipe diameter(mm) | 16-63 | 20-110 | 63-200 | 16-32 | 63-110 | 63-110 | 110-250 | 200-400 | 200-400 | 315-630 | 315-630 | 400-800 | |

| Die head | Double outlet | Single outlet | Single outlet | Four outlet | Single outlet | Double outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet |

| total power(kw) | 91 | 85 | 86.5 | 91 | 85 | 136 | 103 | 114 | 131 | 212 | 220 | 270 | 265 |

Related Machine:

1.Mixer

2.Pipe Crusher

3.Laser Printer

4.Gravimeter

5.Pulverizer

The production process and machine details:

Function :

to load the raw material

Spring loader

Vacuum feeder

Function :

to make the materials fully plasticized, mixed uniformly and then formed through a die.

| Model | SJZ-51 | SJZ-55 | SJZ-65 | SJZ-80 | SJZ-92 | SJZ-110 |

| Screw diameter(mm) | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 | 110/220 |

| Main motor(kw) | 18.5 | 22 | 30/37 | 55 | 110 | 160 |

| Capacity(kgs/h) | 150 | 180 | 300 | 450 | 900 | 1400 |

| Central height(mm) | 1000 | 1000 | 1000 | 1000 | 1150 | 1200 |

| Net weight(kg) | 3000 | 3500 | 4000 | 5500 | 8000 | 12000 |

| Dimensions(m) | 3.6×1.1×2.1 | 3.6×1.1×2.1 | 4.2×1.5×2.4 | 4.7×1.5×2.4 | 6×1.6×2.5 | 5.4×1.8×3 |

Function :

to make the PVC material into a pipe shape

Function :

to shape and cool the pipe

Function :

to cool large-diameter pipes again

Function :

to haul off pipes smoothly

Function :

to cut pipes into a certain length

Function :

for pipe storage

Function :

to shape the outlet or inlet of pipes