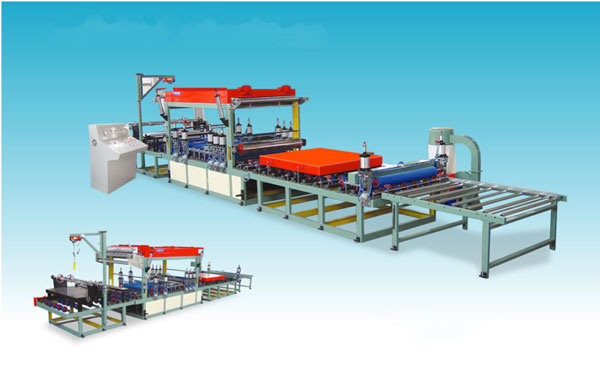

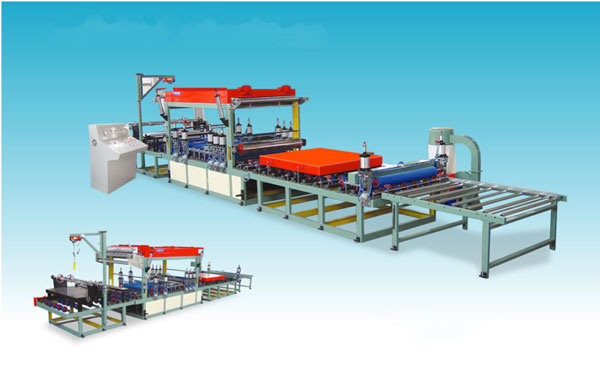

PVC WPC door board machine production line

PVC WPC door board machine production line is mainly used for making wpc door board with different width and thickness. The surface of door board can be treated by printing & coated with glossy oil, heat transfer printing or lamination, which can help the door panel get good decorative effect for house door, kitchen,toilet,balcony and so on.

Related machine:

1.mixing unit

2.door frame making machine

3.door frame hot stamping and lamination machine

4.door board hot stamping and lamination machine

Fill out my online form.

| Model | Max.wide (mm) | Extruder model | Max.output(kg/h) | Motor power(kw) |

| GWMD600 | 600 | SJZ80/156 | 280 | 75 |

| GWMD800 | 800 | SJZ80/156 | 280 | 75 |

| GWMD900 | 900 | SJZ92/188 | 600 | 132 |

| GWMD1000 | 1000 | SJZ92/188 | 600 | 132 |

| GWMD1200 | 1200 | SJZ92/188 | 600 | 132 |

Function :

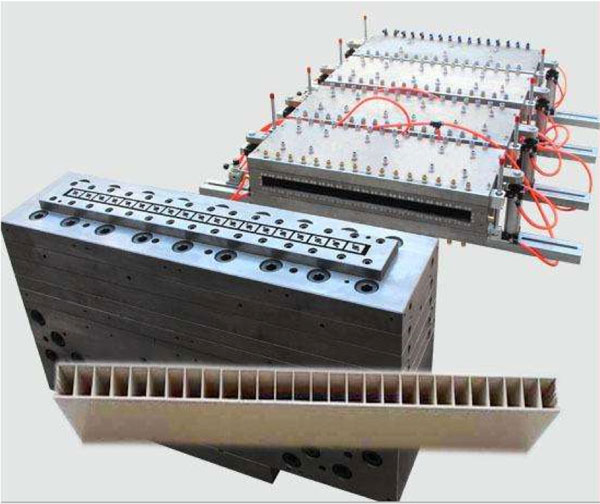

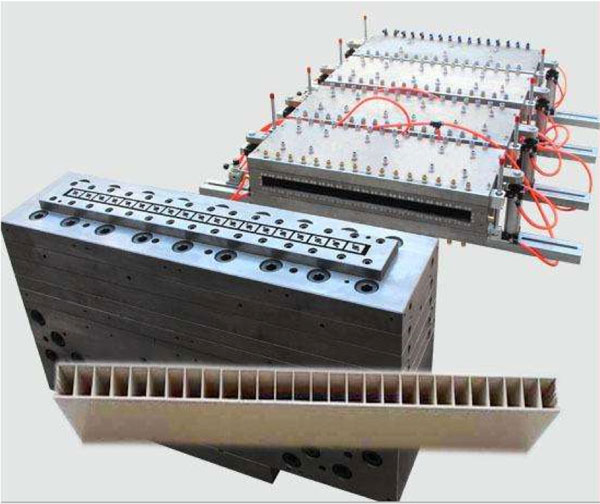

Heat and extrude the pvc to the mould for door board shaping.

Heat and extrude the pvc to the mould for door board shaping.

Function :

The board width and thickness are all custmoized

The board width and thickness are all custmoized

Function :

Cooling and finalize the shape of the profiles

Cooling and finalize the shape of the profiles

Function :

Pull the wpc door board in a uniform speed.

Pull the wpc door board in a uniform speed.

Function :

Cut the wpc door board into fixed length pieces

Cut the wpc door board into fixed length pieces

Function :

Stacking the finished product

Stacking the finished product

Function :

this machine is used to print different pattern on the surface of the board

to make it looks more like real wood.

this machine is used to print different pattern on the surface of the board

to make it looks more like real wood.