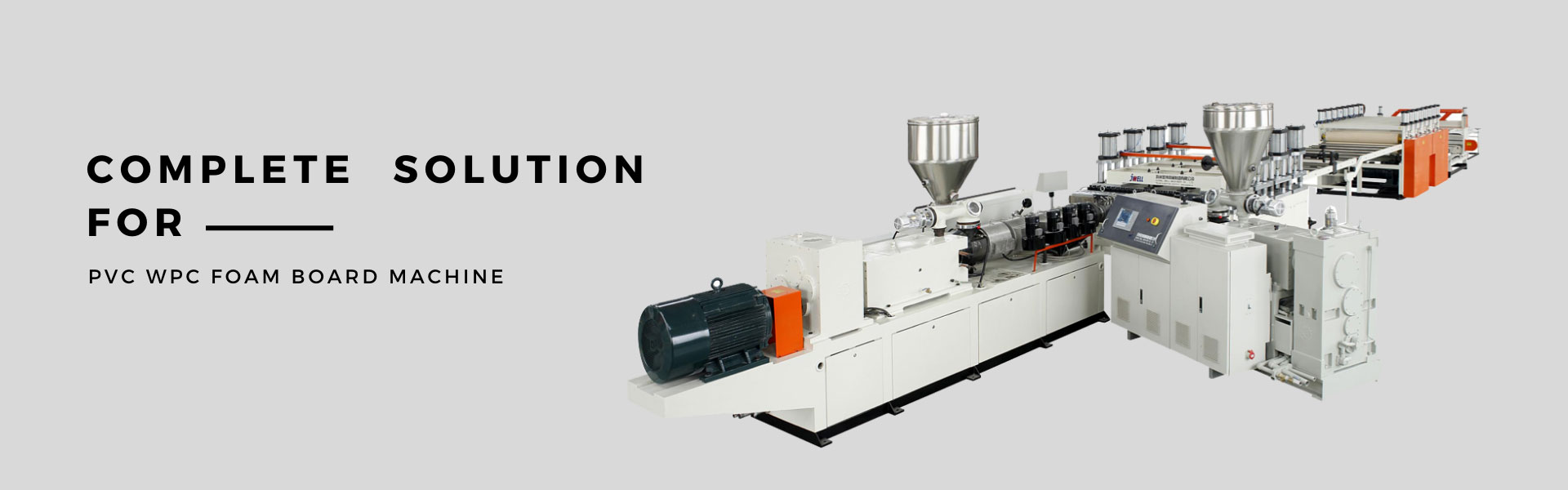

PVC WPC Foam Board Machine

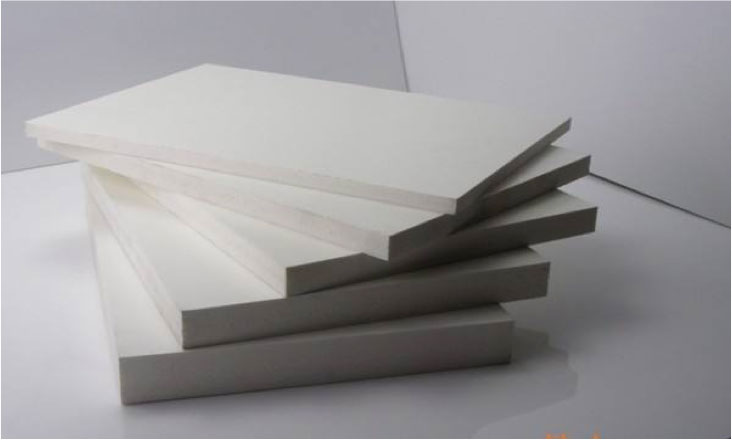

PVC WPC board production line uses PVC and wood fiber as raw material, by semi-crust or full-crust foaming technology, to make WPC solid boards/panels with width for 3-35mm and density for 0.3-0.8gram/cm3, the WPC foam boards are widely used for making furniture panel, construction formwork, partition wall,floor base and door board ….

By for another extruder for co-extrusion, can make surface more hard and brightly.

| Extruder model | Main motor power(kw) | WPC board thickness(mm) | Extrusion Capacity(kg/h) |

| SJSZ65/132 | 37kw | for co-extrusion | 150-200 |

| SJSZ80/156 | 75kw | 3-18 | 250-350 |

| SJSZ80/173 | 90kw | 5-35 | 300-450 |

| SJSZ92/188 | 110kw | 8-45 | 400-500 |

Related machine:

1.High speed mixing unit

2.Plastic crusher

3.Plastic pulverizer

Machine component:

Function :

Melten the raw materials for produce foam boards

Function:

Form and cool the shape of foam boards, make the surface of foam boards become hard.

Function :

Air cooling for the foam boards

Function:

Hall the foam boards to stacker with side cutting device to form the width of foam board to a particular size.

Stock the final products.