Agglomerate Type Pelletizing Line

Agglomerate type pelletizing line is mainly applied to recycle PP, PE, BOPP, BOPET, BOPA, PA66 etc. dry film.

The unit consists of loading device, agglomerator,extruder, die head, screen exchanger, vibrating sieve, dewatering machine. the machine capacity can choose is 100-1000kg per hour.

| Model | SJ-85 | SJ-90 | SJ-100 | SJ-120 | SJ-150 | SJ-180 | SJ-200 |

| Screw diameter(mm) | 85 | 90 | 100 | 120 | 150 | 180 | 200 |

| Main motor(kw) | 55 | 75-90 | 90 | 110-132 | 160-200 | 250-285 | 285-315 |

| Capacity(kgs/h) | 150-200 | 200-300 | 300-350 | 400-500 | 500-600 | 600-800 | 800-1000 |

Related Machine:

The recycling process and machine details:

Function :

to load plastic film into the agglomerator

film roll feeding device

function:

to feed the plastic roll film

Function :

this device is applied to crusher and plastize the plastic film or woven bag.

Function :

melt plastic and exhaust waste air with degassing zones.

double stage can get more good quality final granules

| Model | SJ-85 | SJ-90 | SJ-100 | SJ-120 | SJ-150 | SJ-180 | SJ-280 |

| Screw diameter(mm) | 85 | 90 | 100 | 120 | 150 | 180 | 200 |

| Main motor(kw) | 55 | 75-90 | 90 | 110-132 | 160-200 | 250-285 | 285-315 |

| Capacity(kgs/h) | 150-200 | 200-300 | 300-350 | 400-500 | 500-600 | 600-800 | 800-1000 |

Function :

Filter out impurities

| Model | Screen Diameter(mm) | Output(kg) | Heating Power(kw) |

| 160 | 164 | 900 | 6.6 |

| 200 | 200 | 1300 | 7.8 |

| 260 | 264 | 2200 | 12.4 |

| 300 | 306 | 2700 | 14 |

Function :

Form plasticized plastic to a particular shape for follow-up process.

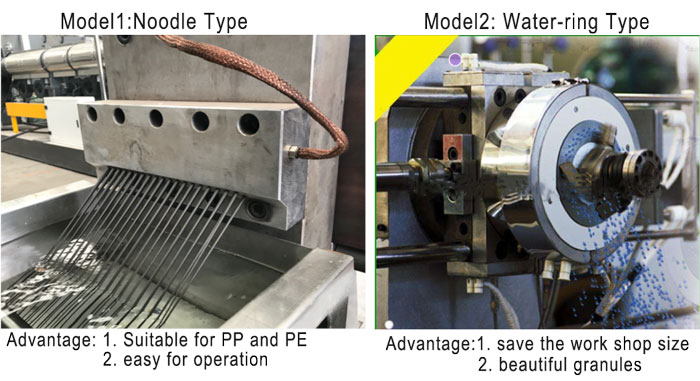

Water-ring type Cutting Device

Function :

Cut material out from die head to regular shape. Rinse to cool and shape up.

strand type cutting Device

Function:

Cut noodles to get regular plastic pellets.

Function :

Remove water by centrifugal force

Water-ring type Cutting Device

Function :

Select right sized plastic granules,air blower and silo is for granules storage