Dose Feeding Rigid Plastic Pelletizing Line

Dose feeding rigid plastic pelletizing line is suitable for crushed rigid plastic flakes and agglometed plastic.

Capacity of dose feeding pelletizing line

150-800kg/h

Fill out my online form.

Related Machine:

The recycling process and machine details:

Function :

Feed wet plastic scraps into the screw to melt and plasticize it.Exhaust air with degassing zones

mother extruder

| Model | Screw diameter(mm) | L/D | Motor power(kw) | Central height | Output(kg/h) |

| SJ100/33 | 100 | 33 | 55 | 1000 | 150 |

| SJ120/33 | 120 | 33 | 75 | 1000 | 300 |

| SJ140/33 | 140 | 33 | 110 | 1100 | 450 |

| SJ160/33 | 160 | 33 | 160 | 1100 | 600 |

| SJ180/33 | 180 | 33 | 200 | 1100/1300 | 800 |

| SJ200/33 | 200 | 33 | 280 | 1300 | 1000 |

bady extruder

| Model | Screw Diameter(mm) | L/D | Motor power(kw) | Central height | Output(kg/h) |

| SJ100/10 | 100 | 10 | 22 | 1000 | 150 |

| SJ120/10 | 120 | 11 | 30 | 1000 | 300 |

| SJ140/10 | 140 | 12 | 37 | 1100 | 450 |

| SJ160/10 | 160 | 13 | 45 | 1100 | 600 |

| SJ180/10 | 180 | 14 | 55 | 1100/1300 | 800 |

| SJ200/10 | 200 | 15 | 75 | 1300 | 1000 |

Function :

Filter out impurities

| Model | Screen Diameter(mm) | Output(kg) | Heating Power(kw) |

| 160 | 164 | 900 | 6.6 |

| 200 | 200 | 1300 | 7.8 |

| 260 | 264 | 2200 | 12.4 |

| 300 | 306 | 2700 | 14 |

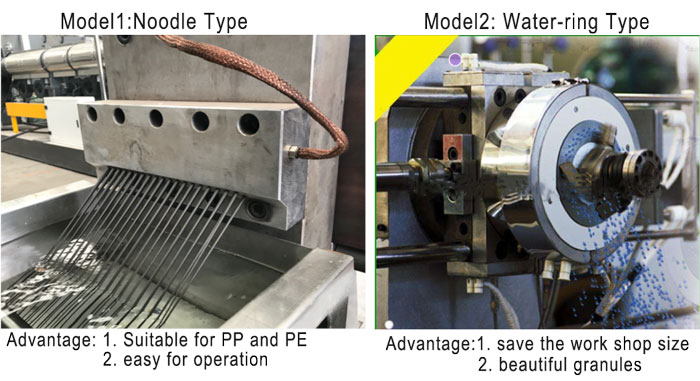

Function :

Form plasticized plastic to a particular shape for follow-up process.

Function :

Cooling the noodle coming from die head.

Function :

Cut plastic strips to get regular plastic pellets.

Function :

Cut material out from die head to regular shape. Rinse to cool and shape up.

Function :

Remove water by centrifugal force

Remove water by centrifugal force

Function :

Select right sized plastic granules,air blower and silo is for granules storage