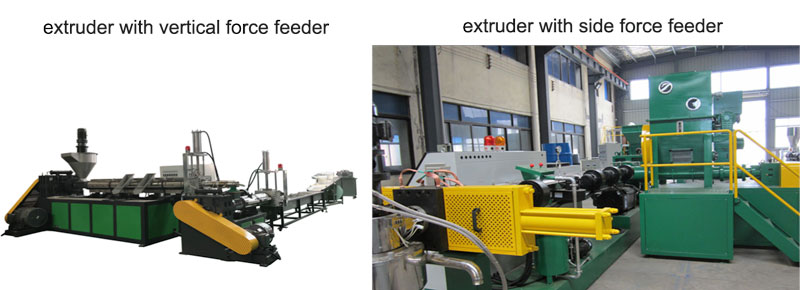

Force Feeding Pelletizing Line

This pelletizing extruder has special screw design and different configuration, it is suitale for the recycling of PP, PE, BOPP, BOPET, BOPA, PA66, etc. Dry film or rigid flakes. Vertical force feeding and side force feeding could help the extruder deal with film and rigid plastic at the same time . The surface of the screw and barrel have been special treated so that the screw and barrel are wearable. They have very good wear properties and mixing effect and the production capacity is high. The extruder has the vacuum vented design which can exhaust the vapor or gas during the production so that the output are more stable and the pellets are more uniform.

| Model | Screw dia(mm) | L/D | Screw speed(rpm) | Power of main motor(kw) | Output(kg/h) | |

| GWP100 | 100 | 33/1 | 20-150 | 75-90 | 200-300 | |

| GWP120 | 120 | 33/1 | 20-150 | 110-132 | 300-400 | |

| GWP150 | 150 | 33/1 | 20-150 | 160-200 | 400-500 | |

| GWP180 | 180 | 33/1 | 20-150 | 250-315 | 600-800 | |

| GWP200 | 200 | 33/1 | 20-150 | 250-315 | 800-1000 | |

Related machine:

The recycling process and machine details:

Function :

Feed wet plastic film into the screw to melt and plasticize it. Exhaust air with degassing zones.

| mother extruder | |||||

| Model | Screw diameter(mm) | L/D | Motor power(kw) | Central height | Output(kg/h) |

| SJ100/33 | 100 | 33 | 55 | 1000 | 200 |

| SJ120/33 | 120 | 33 | 75 | 1000 | 300 |

| SJ140/33 | 140 | 33 | 110 | 1100 | 450 |

| SJ160/33 | 160 | 33 | 160 | 1100 | 600 |

| SJ180/33 | 180 | 33 | 200 | 1100/1300 | 800 |

| SJ200/33 | 200 | 33 | 280 | 1300 | 1000 |

| bady extruder | |||||

| Model | Screw Diameter(mm) | L/D | Motor power(kw) | Central height | Output(kg/h) |

| SJ100/10 | 100 | 10 | 22 | 1000 | 200 |

| SJ120/10 | 120 | 11 | 30 | 1000 | 300 |

| SJ140/10 | 140 | 12 | 37 | 1100 | 450 |

| SJ160/10 | 160 | 13 | 45 | 1100 | 600 |

| SJ180/10 | 180 | 14 | 55 | 1100/1300 | 800 |

| SJ200/10 | 200 | 15 | 75 | 1300 | 1000 |

Function :

Filter out impurities

| Model | Screen Diameter(mm) | Output(kg) | Heating Power(kw) |

| 160 | 164 | 900 | 6.6 |

| 200 | 200 | 1300 | 7.8 |

| 260 | 264 | 2200 | 12.4 |

| 300 | 306 | 2700 | 14 |

Function :

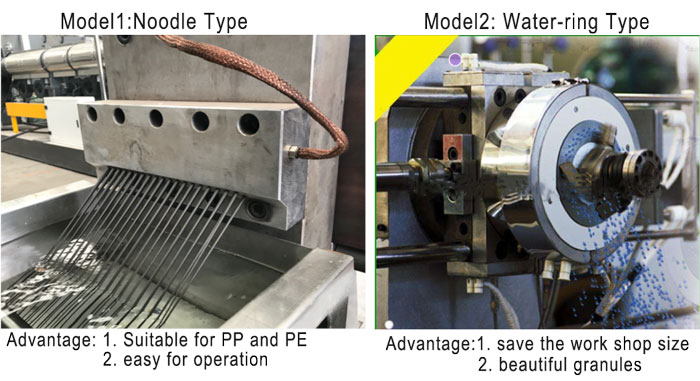

Form plasticized plastic to a particular shape for follow-up process.

Cooling the noodle coming from die head.

Cut plastic strips to get regular plastic pellets.

Function :

Cut material out from die head to regular shape. Rinse to cool and shape up.

Remove water by centrifugal force

Select right sized plastic granules,air blower and silo is for granules storage