PET Packing Strap Making Machine

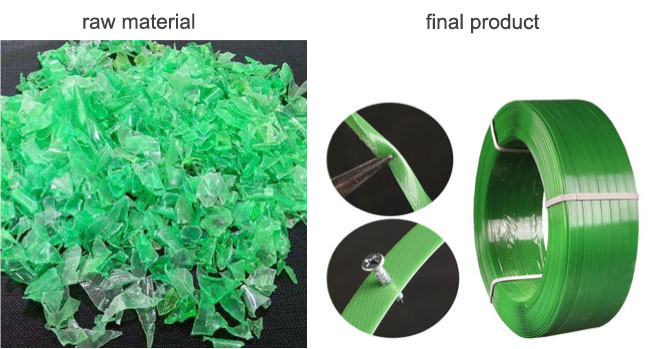

Greenwill PET packing strap making machine which can produce one and two strap in one time,

it adopt the melting pump and pressure sensor to ensure the production stable and strap quality control.The raw material is 100% recycled pet flakes from the waste pet bottles,or virgin material or mixed with each other. Advantage:

1.Use 100% Recycled PET Flakes to reduce the cost

2.Good dehumidifer drying system(Crystallization system optional ) to ensure the material equal dryer to produce high quality strapping.

Related machine:

1. pp packing strap making machine

2. pet bottle recycling washing line

| Model | Capacity (kg/h ) | Strap size (mm) | Installed Power | Manpower | Machine size | Manpower | Machine size | |

| (KW) | (L*W*H m) | (L*W*H m) | ||||||

| SJ65/33 Single strap | 50~60 | 9~19 | 85 | 1~2 | 35*4*5 | 1~2 | 35*4*5 | |

| SJ75/33 Single strap | 80~100 | 9~19 | 100 | 1~2 | 38*4*6 | 1~2 | 38*4*6 | |

| SJ75/33 Double strap | 80~120 | 9~19 | 110 | 1~2 | 40*4*6 | 1~2 | 40*4*6 | |

| SJ90/33 Double strap | 120~150 | 9~19 | 150 | 1~2 | 45*5*7 | 1~2 | 45*5*7 | |

| SJ120/33 Double strap | 150~200 | 9~19 | 220 | 1~2 | 45*5*7 | 1~2 | 45*5*7 | |

Content

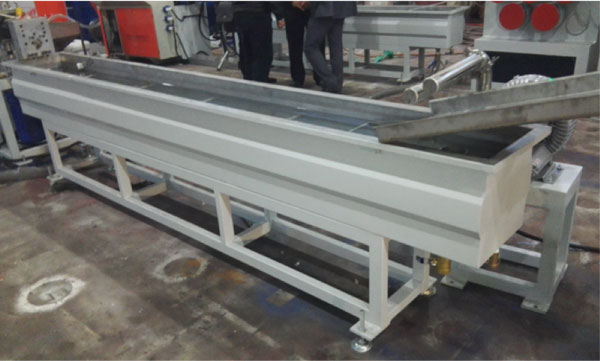

This system is used for PET pre-crystallization ,and ensure the material equal dryer to produce high quality PET strap.

Function:

melt pet flakes and extrude the material to the mould

Filter:impurities from raw materials to improve the quality of finished products

melt pump: make the plastic float more smoothly

mould: shap the pet starp at special size.

Function: Tration,heat stretch, and emboss the belt strap.