PP PE Bottle Washing Line

Made by Ivima technology, which is used to recycle PP PE bottles.

By crushing or shredding, washing and drying.

You will get clean and dry PP PE bottle flakes, the flake’s size can be 12-16mm.

With a pelletizing line, the waste plastic can be reused for producing baskets, pipes, bags, injection etc.

| The capacity of PP PE bottle washing line | |

| 1. 300kg per hour | 2. 500kg per hour |

| 3. 1000kg per hour | 4. 1500kg per hour |

| 5. 2000kg per hour | 6. 3000kg per hour |

The recycling process and machine details:

Function:

Crush waste plastic film to suitable size. Good for washing and drying.

| Model | Feed mouth size(mm) | Main motor power(kw) | Moving knife Qty.(pcs) | Fixed knife Qty.(pcs) | Rotor Diameter(mm) | Output(kg/h) |

| GWPS-Z 600 | 600×600 | 22-37 | 6/10 | 4 | φ500 | 400 |

| GWPS-Z 800 | 800×800 | 37-75 | 6/10 | 4 | φ600 | 600 |

| GWPS-Z 1000 | 1000×1000 | 55-110 | 10/14 | 4/6 | Φ700 | 800 |

| GWPS-Z 1200 | 1200×1000 | 90-132 | 10/14/18 | 4/6 | Φ800 | 1000 |

| GWPS-Z 1400 | 1400×1000 | 110-200 | 14/18 | 4/6 | Φ800 | 1500 |

Function :

Remove dirt or sand by friction paddles with or without water.

Model 1: screw type friction washer

Model 2: Wet friction washer

Function :

It use hot water to wash the oil and chemical pollutants.

Function :

Wash away dirt with stirring paddles.

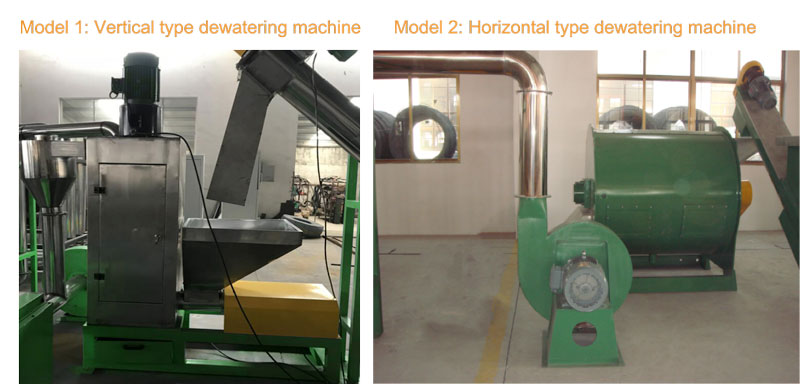

Function :

Dry the crushed cleaning rigid plastic scraps after being washed.

Function :

Further Drying washed rigid plastic scraps.

Function:

Adopt specific gravity to separate the label and dust from plastic pp/pe scrap.