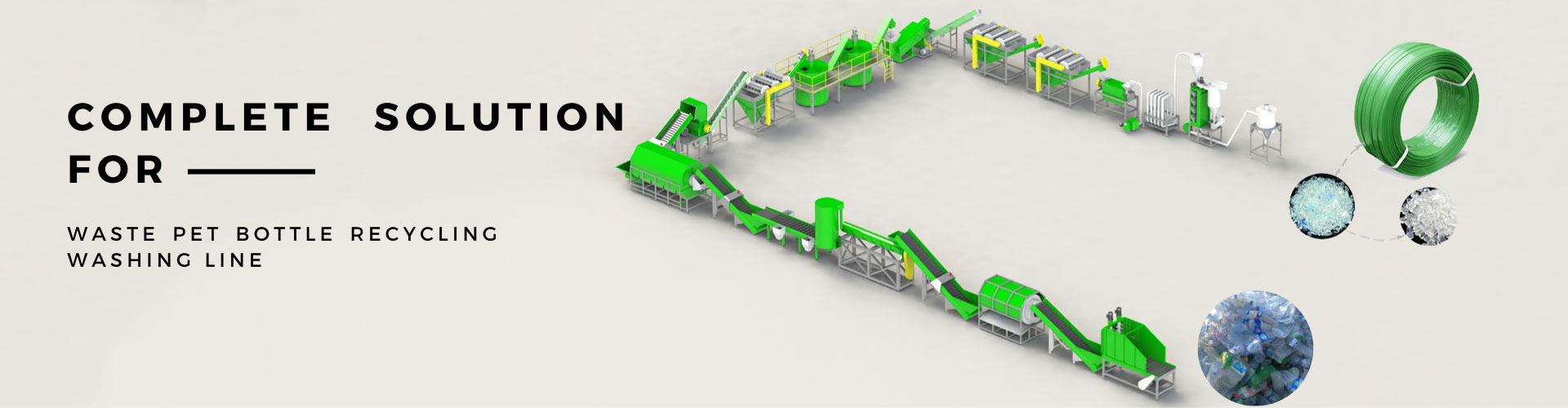

Waste Pet Bottle Recycling Washing Line

Made by Ivima technology, which is used to recycle waste pet bottles.

By sorting, crushing, washing and drying.

You will get clean and dry pet flakes, the flakes size can be 12-14mm, we can also make it to be 7-25mm as customized.

These pet flakes can be used to make pet packing strap and pet fiber directly.

The pet flakes can be used to make pet granules for making pet bottles, pet sheet and pet injection material again.

| the capacity of the pet wahsing line | |

| 1. 300kg per hour | 2. 500kg per hour |

| 3. 1000kg per hour | 4. 1500kg per hour |

| 5. 2000kg per hour | 6. 3000kg per hour |

Related Machine:

1.PET Pelletizing Machine

2.Dehumidifyer and Crystallizer and Dryer

3.Pet Packing Strap Machine

The recycling process and machine details:

Function:

This machine is applied to opening the pet bales by force:

vertical type:

horizontal type:

Function:

This machine is used for material collection and conveying.

Function:

This machine is used to make the pressed pet bottles loose and remove soil sand, stone and some caps.

Horizontal type

Vertical type:

Function:

This machine use many small blades to scrape the label and caps of the pet bottles. The floating water will take the label and caps out of the machine.

Air type label remover:

Function:

This machine use many small blades to scrape the label and caps of the pet bottles. The air fan will take the label out of the machine.

Function:

This sorting table is applied for workers standing on both sides, and picking out other pollutants, like paper, glass, pvc bottles and irons etc. The metal detector will check for any metal item and give feed back for worker to find it out.

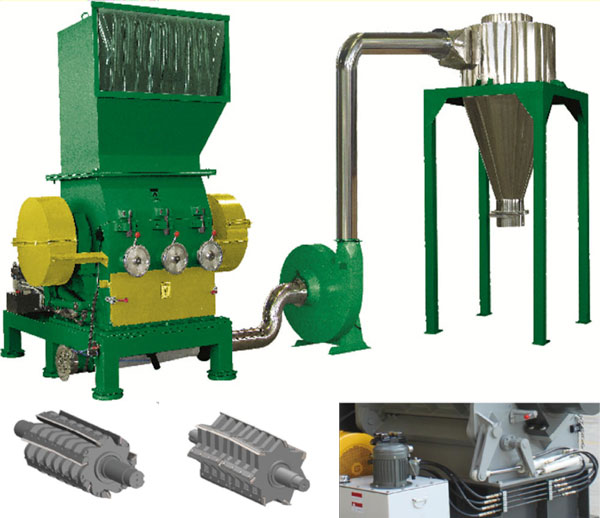

Fuction:

Pet bottle crusher is applied to crushing the pet bottles to get pet scraps. A strong crusher is the most important part for the pet washing line. The size of the pet flakes is customized from 7 to 25mm. Our crusher is very stable, and the chamber open by hydraulic for easy operation, our crusher can work with water for pre-washing.

| model | GWP600 | GWP800 | GWP1000 | GWP1200 | GWP1400 |

| capacity | 200-300kg | 500kg | 800kg | 1000kg | 1500kg |

| motor | 18.5/22/30kw | 37kw/45kw | 55kw | 75kw | 110kw |

| rotation speed | 630rpm | 630rpm | 630rpm | 650rpm | 650rpm |

Function:

Screw loader is applied to loading the pet bottle scrap to next step, and take dirty water out.

Function :

This washing tank is applied to washing and separating the cap/label from pet flakes, inclined design washing tank can save machine cost. Material contact with water are all made of stainless steel 304.

Function:

This friction washer is applied to making the dirt loose by friction, one water pump spray water from the top and the dirt will be taken away by the water.

Function:

This machine use hot water and washing chemical to wash the oil and glue. Material contact with water are made of stainless steel 304.

Function:

This machine use high speed centrifuge to remove the water. The final pet flakes moisture will be about 3-5%.

Function:

This machine is used to dry the pet flakes by hot air, to make the pet flakes moisture less than 1%. Material of the pipe is stainless steel 304

Function:

This machine use material specific gravity to separate the label and dust from pet flakes. The fan power is adjustable.

Function:

This silo is made of stainless steel 304. Air cylinder is controlled by PLC. Customer can full fill the jumbo bag automatically. Two out-let is used for easy operation.